技术立业丨利元亨EIS充放电测试仪:电池检测领域的核心利器

发布时间:2025-06-29 10:05分类: 科技 浏览:12评论:0

在当今快速发展的新能源领域,电池性能的精准评估成为推动行业进步的关键之一。利元亨新推出的EIS充放电测试仪,以其卓越的技术参数和强大的功能特性,为电池研发、生产以及质量控制带来了全新的解决方案。

利元亨EIS充放电测试仪,作为技术集成的典范,通过将传统化成分容功能与电化学阻抗谱(EIS)检测技术深度融合,实现了两种工艺的协同运行。其核心功能涵盖两方面:化成分容,完成电池的充电/放电激活、容量分选等关键工艺;EIS检测,通过电化学阻抗谱测试,实时获取电池的SEI膜阻抗、电荷转移阻抗等核心参数,为电池状态提供多维度数据支撑。

利元亨EIS充放电测试仪通过硬件模块与软件控制的无缝衔接,将EIS检测与化成分容功能高度集成。这一设计显著简化了工步配置,支持灵活调节测试流程,并通过详细的参数设置与异常标记功能,确保测试过程高效精准。相比传统设备切换与电池搬运带来的效率损耗,该设备以一体化架构实现工艺流程的最优化,为大规模生产提供稳定支撑。

•化成异常识别:对比正常与异常电池的阻抗谱,异常电池Rf值明显降低,表明SEI膜未充分形成,有效预警化成缺陷;

•首效差异分析:低首效电芯的Rf,Rct均降低,揭示首效异常与电化学性能的关联性;

•ACT极化检测:极化大电芯的Rf值增大,直观反映极化异常;

•容量异常识别:低容电芯(1%)的Rf值数据变化显著,为容量筛选提供科学依据。

利元亨EIS充放电检测设备,不仅是技术参数的集合体,更是电池科学与工程实践的桥梁。其 高精度、高效率、高适配性 的特性,正在重新定义电池检测的行业标准。在新能源产业迈向高质量发展的进程中,这台设备无疑将成为推动技术革新、保障产品质量的核心力量。

The Technology of the Industry | Lyric EIS Charge-Discharge Tester: The Core Tool in Battery Detection

In today's rapidly evolving new energy sector, accurate assessment of battery performance has become one of the key drivers of industry advancement. The latest EIS charge-discharge tester launched by Lyric, with its outstanding technical parameters and powerful functional features, offers a brand-new solution for battery R&D, production, and quality control.

Lyric's EIS charge-discharge tester, as a model of technological integration, achieves the coordinated operation of two processes by deeply merging traditional formation and grading functions with electrochemical impedance spectroscopy (EIS) detection technology. Its core functionalities encompass two aspects: Formation and Grading – Performing key processes such as battery charge/discharge activation and capacity sorting. EIS Testing – Acquiring critical parameters like SEI film impedance and charge transfer resistance in real time through electrochemical impedance spectroscopy, providing multidimensional data support for battery status analysis.

Lyric's EIS charge-discharge tester achieves high integration of EIS detection with formation and grading functions through seamless hardware-software coordination. This design significantly simplifies process configuration, supports flexible test flow adjustments, and ensures efficient and precise testing with detailed parameter settings and anomaly flagging capabilities. Compared to the efficiency losses caused by equipment switching and battery handling in traditional setups, this device optimizes the production process with its integrated architecture, delivering stable support for large-scale manufacturing.

High-Precision Detection: Comprehensive Scientific Analysis Across Full Frequency Bands

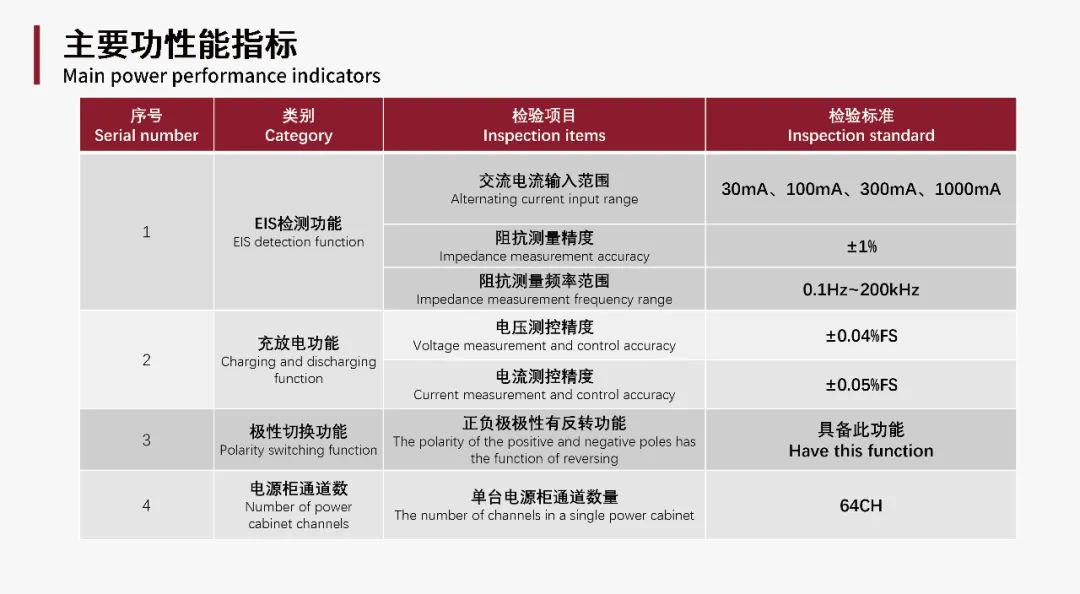

The equipment employs wide-band AC signals (0.1Hz to 200kHz) and high-precision sampling technology, combined with range adjustment functionality, to meet the impedance measurement requirements of various battery types including consumer-grade pouch cells, power-oriented prismatic cells, and blade batteries. The EIS detection features a wide excitation current input range with 4 adjustable ranges, achieving impedance measurement accuracy of ±1% and covering a frequency range from 0.1Hz to 200kHz. The charge-discharge function achieves voltage and current measurement control accuracies of ±0.04% FS and ±0.05% FS respectively, ensuring reliable data acquisition. Additionally, the equipment features polarity switching capability and offers up to 64 channels per power cabinet, meeting high-throughput testing requirements.

Multi-Type Anomaly Detection: Data-Driven Risk Warning

By analyzing battery parameters including ohmic resistance (Rs), SEI film resistance (Rf), and charge transfer resistance (Rct), the system can accurately identify over 10 types of faults such as internal short circuits, lithium plating, and consistency defects. The technology demonstrates outstanding sensitivity in formation, grading and structural defect detection:

• Formation Anomaly Identification: By comparing the impedance spectra of normal and abnormal batteries, the Rf value of abnormal batteries shows a significant decrease, indicating insufficient SEI film formation and effectively warning of formation defects.

• First-Cycle Efficiency Analysis: Batteries with low initial efficiency show decreased Rf and Rct values, demonstrating the correlation between first-cycle performance and electrochemical characteristics;

• ACT Polarization Testing: Cells with high polarization demonstrate increased Rf values, directly indicating polarization abnormalities

• Capacity Anomaly Identification: Low-capacity cells (1%) display prominent Rf value variations, offering scientific basis for capacity screening.

Intelligent Data Processing: Closed-Loop Management Enhances Manufacturing Efficiency

Test data is automatically analyzed and uploaded to the MES system, enabling real-time monitoring of battery status. The system supports channel selection, data comparison, and Nyquist/Bode plot display, with export capabilities for both image and Excel files to facilitate in-depth analysis. Meanwhile, the function of displaying work step information and detailed data, combined with intelligent impedance value calculation, ensures the accuracy and efficiency of data analysis. This closed-loop management mechanism not only reduces safety risks but also significantly improves production capacity and product yield rates.

A New Benchmark for Domestic Alternatives: Addressing Industry Pain Points

Currently, imported EIS equipment remains prohibitively expensive with limited applicability, failing to meet batch testing requirements. Meanwhile, the lack of electrochemical data during mass production makes it difficult to identify internal battery defects in advance. Lyric’s EIS charge-discharge tester takes independent intellectual property rights as the core, filling the technical gap of domestic high-end testing equipment. With its high precision, high reliability and cost advantages, it provides new energy enterprises with solutions that combine technical advancement and economic feasibility, promoting the comprehensive upgrade of battery testing from "experience-based judgment" to "data-driven".

Lyric’s EIS charge-discharge tester is not just a collection of technical parameters, but also a bridge between battery science and engineering practice. Its characteristics of high precision, high efficiency and high adaptability are redefining the industry standards for battery testing. In the process of the new energy industry moving towards high-quality development, this equipment will undoubtedly become the core force to promote technological innovation and ensure product quality.

相关文章

- 演讲预告 | 相约重庆,和利时邀您共赴交通运输新技术新成果推广大会

- 金山云发布第九代云服务器 携手英特尔开启智算时代新篇章

- 国庆献礼 | 我们的责任与担当

- 华力创通创新探索“直播带岗”新路径

- 打造铁路信号智能运维“超级医生”——“和行”轨道交通大模型让运维更高效

- 协合新能源受邀出席第二届东盟电池技术会议 分享储能安全预警技术创新成果

- 智汇长安,赋能未来——和利时西安培训中心正式启动,开启工业智能化人才培养新篇章

- 智汇长安,赋能未来——和利时西安培训中心正式启动,开启工业智能化人才培养新篇章

- 从基础认知到高阶应用!《AI赋能企业跃迁课程包》全面上线

- 和利时成功入选国家2024年实数融合典型案例名单